I decided to take a few pics of my brake job and turn them into a DIY. I know there are a couple threads out there, but IIRC, they don't do a step by step with pics. Here goes.

First, break the lug nuts loose. Lift and support the axle with jack stands. I leave the jack in place as an extra measure.

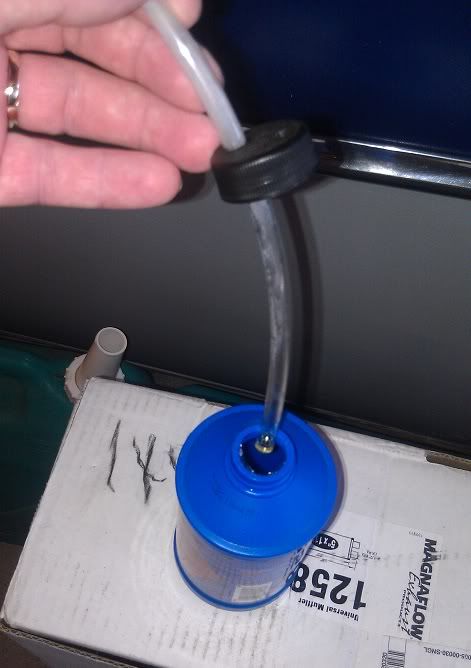

Remove the wheels and attach a bleed container to the bleeder fitting. The container should have a few ounces of clean brake fluid in it.

![Image]()

![Image]()

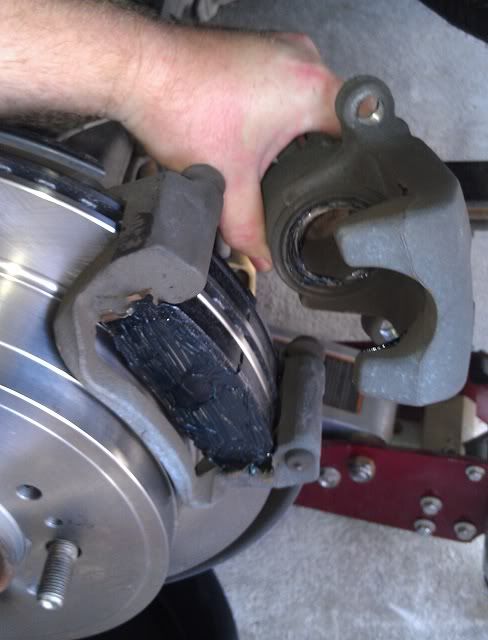

Loosen the bleeder and compress the caliper by wedging a flat blade screwdriver between the brake pad and the rotor, then pry the pad away from the rotor. Do not go between the pad and the caliper piston as you can tear the dust boot or damage the caliper piston.

![Image]()

Remove the caliper from the caliper bracket and lay it on top of the axle. Do not let it hang by the brake hose.

![Image]()

![Image]()

Remove the brake pads from the caliper bracket.

![Image]()

Remove the caliper bracket.

![Image]()

![Image]()

Clean or replace the brake hardware that the brake pads fit into.

![Image]()

![Image]()

Remove the disc brake rotor. If it is seized to the hub, use the threaded holes provided by threading a bolt through the hole to press the rotor from the hub.

![Image]()

![Image]()

![Image]()

With the rotor removed, inspect the parking brake shoes and clean or replace if necessary.

![Image]()

Compare the new rotor to the old one to be sure they match. It's not uncommon to find brake rotors that are misboxed from the manufacturer. You will also need to transfer the rubber inspecion hole plug from your old rotor to the new one. If you have your old rotors turned/machined, remove it before doing so.

![Image]()

Clean the new rotor with brake cleaner and dry it with a paper towel. Don't use a shop rag. The fibers melt to the pads and rotor, not to mention the detergent they are washed in. Paper towels or compressed air is best.

![Image]()

![Image]()

Clean the hub with a wire brush and apply a light coat of anti-seize compound. Don't use too much. If it gets behind the rotor, it can warp it as the lug nuts are torqued.

![Image]()

![Image]()

Install the new (or machined) rotor and run up one lug nut finger tight. This will hold the rotor to the hub while you install the pads and caliper later.

![Image]()

Your new brake pads should be chamfered on the ends to prevent squeaks. If they are not chamfered, it's ok to add the chamfer with a bench grinder or file.

![Image]()

![Image]()

Apply brake caliper lubricant to the back of the brake pad...NOT THE FRICTION SURFACE... to reduce vibration transfer to the caliper. This will reduce squeaks. Also apply lube to the ends of the pad where they slide in the caliper bracket.

![Image]()

![Image]()

Apply caliper lube to the caliper bracket anywhere the brake pad will contact it. Also lube the guide pin holes where the caliper attaches to the bracket.

![Image]()

![Image]()

Reinstall the caliper bracket.

![Image]()

Insert the brake pads into the caliper bracket. Clean the caliper guide pin/bolts and lubricate them. Lubricate the caliper piston and install the caliper.

![Image]()

![Image]()

![Image]()

![Image]()

![Image]()

Top off the master cylinder with DOT 3 brake fluid. Remove the lug nut that was installed to hold the rotor in position, then reinstall the wheel. Repeat for the other side.

![Image]()

![Image]()

Don't forget to pump the brakes to position the pads against the rotors before driving it. There is no reason to bleed the system. Using this method, there is virtually no way to draw air into the brake lines. As you compress the caliper, old fluid is pushed into your bleed container. As the caliper reaches full compression, tighten the bleed screw before removing the hose from the bleeder.

Remember to ALWAYS torque the wheels to specification by hand. These trucks are prone to rotor warpage and overtightening the lug nuts is an easy way to warp them.

![Image]()

First, break the lug nuts loose. Lift and support the axle with jack stands. I leave the jack in place as an extra measure.

Remove the wheels and attach a bleed container to the bleeder fitting. The container should have a few ounces of clean brake fluid in it.

Loosen the bleeder and compress the caliper by wedging a flat blade screwdriver between the brake pad and the rotor, then pry the pad away from the rotor. Do not go between the pad and the caliper piston as you can tear the dust boot or damage the caliper piston.

Remove the caliper from the caliper bracket and lay it on top of the axle. Do not let it hang by the brake hose.

Remove the brake pads from the caliper bracket.

Remove the caliper bracket.

Clean or replace the brake hardware that the brake pads fit into.

Remove the disc brake rotor. If it is seized to the hub, use the threaded holes provided by threading a bolt through the hole to press the rotor from the hub.

With the rotor removed, inspect the parking brake shoes and clean or replace if necessary.

Compare the new rotor to the old one to be sure they match. It's not uncommon to find brake rotors that are misboxed from the manufacturer. You will also need to transfer the rubber inspecion hole plug from your old rotor to the new one. If you have your old rotors turned/machined, remove it before doing so.

Clean the new rotor with brake cleaner and dry it with a paper towel. Don't use a shop rag. The fibers melt to the pads and rotor, not to mention the detergent they are washed in. Paper towels or compressed air is best.

Clean the hub with a wire brush and apply a light coat of anti-seize compound. Don't use too much. If it gets behind the rotor, it can warp it as the lug nuts are torqued.

Install the new (or machined) rotor and run up one lug nut finger tight. This will hold the rotor to the hub while you install the pads and caliper later.

Your new brake pads should be chamfered on the ends to prevent squeaks. If they are not chamfered, it's ok to add the chamfer with a bench grinder or file.

Apply brake caliper lubricant to the back of the brake pad...NOT THE FRICTION SURFACE... to reduce vibration transfer to the caliper. This will reduce squeaks. Also apply lube to the ends of the pad where they slide in the caliper bracket.

Apply caliper lube to the caliper bracket anywhere the brake pad will contact it. Also lube the guide pin holes where the caliper attaches to the bracket.

Reinstall the caliper bracket.

Insert the brake pads into the caliper bracket. Clean the caliper guide pin/bolts and lubricate them. Lubricate the caliper piston and install the caliper.

Top off the master cylinder with DOT 3 brake fluid. Remove the lug nut that was installed to hold the rotor in position, then reinstall the wheel. Repeat for the other side.

Don't forget to pump the brakes to position the pads against the rotors before driving it. There is no reason to bleed the system. Using this method, there is virtually no way to draw air into the brake lines. As you compress the caliper, old fluid is pushed into your bleed container. As the caliper reaches full compression, tighten the bleed screw before removing the hose from the bleeder.

Remember to ALWAYS torque the wheels to specification by hand. These trucks are prone to rotor warpage and overtightening the lug nuts is an easy way to warp them.